Leading company in high-precision image inspection with AI

SiriusVision contributes to product quality improvement from pre-printing to during printing and before delivery, using our proprietary high-precision image inspection algorithm.

In the coming era of declining working population, we support future manufacturing sites with AI technology that provides pass/fail judgments equivalent to those of skilled inspectors.

Our Software

Products

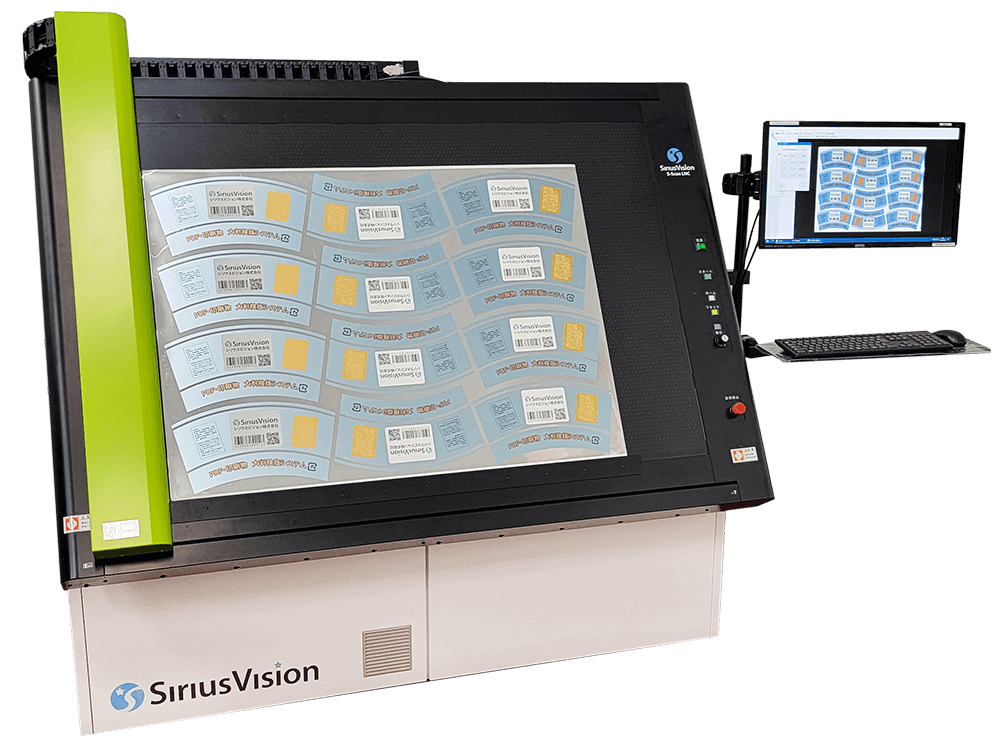

SiriusVision’s Machine Vision (Image Inspection) System – takes only the defects you want to take –

We are researching and developing new technologies for automation and labor saving at production sites, as well as improving usability, accuracy and speed performance for our original Machine Vision (Image Inspection) System software. In addition, we can propose an automatic Machine Vision (Image Inspection) System / inspection system that matches customer needs by combining it with the most suitable imaging / transport equipment.

-

Plate inspection system

From proofreading and printing inspection of printed matter to continuous and sampling inspection of sheet-fed products

-

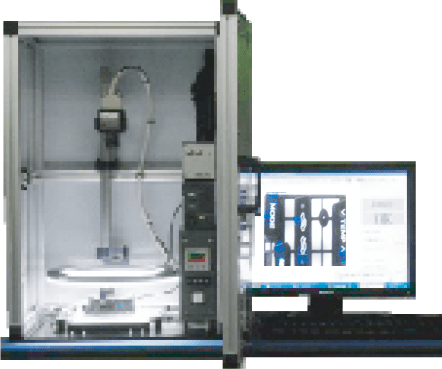

Container inspection

Highly accurate inspection of print quality and appearance quality on the entire surface of various bottles and containers

-

Substrate / article inspection

Printed circuit board, special sheet, molded product print / pattern quality and Appearance Inspection (Automatic Visual Inspection)

-

Seal label inspection

Machine Vision (Image Inspection) System for Print Quality Inspection of roll products

-

Card inspection

Conveyor belt automatic inspection machine for single-wafer labels, cards and sheets

-

Blanks inspection

Blanks dedicated Machine Vision (Image Inspection) System capable sided inspection

-

Inspection unit

Install cameras, lighting, etc. in existing equipment according to your desired inspection specifications